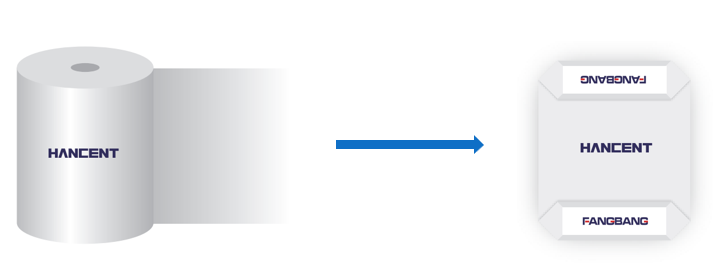

This advanced Paper Sack Tuber Paper Valve Machine utilizes double-sided coated polypropylene tubing to efficiently produce valve-sealed square-bottom plastic sacks, delivering an optimized solution for high-speed industrial bag production.

Key Features & Advantages:

1. Stable High-Speed Output: Maintains consistent production efficiency at 15 pieces/minute for uninterrupted workflow

2. Innovative Bag Formation Technology:

• Negative Pressure Multi-Stage Opening System: Ensures precise valve integration and uniform bag shaping

• Vacuum-Assisted Bottom Sealing Transfer: Enhances structural integrity while minimizing material stress

3. Cost-Effective Operation: Proprietary engineering solutions reduce energy consumption and material waste, directly lowering client operational expenses

4. Industrial-Grade Performance: Engineered for continuous operation in demanding environments including cement plants, chemical facilities, and agricultural processing units

Optimal Application Spectrum:

Specifically designed for mass manufacturing of industrial packaging in:

✓ Bulk powder handling (cement, gypsum, fly ash)

✓ Granular material containment (fertilizers, grains, minerals)

✓ Chemical product packaging (resins, polymers, industrial compounds)

Technical Superiority:

Combines German-engineered motion control systems with Japanese precision manufacturing standards, ensuring exceptional product consistency and minimal maintenance requirements.

| TECHNICAL DATA | FB-S120 NEW |

| Sack Width | 400~620mm |

| Sack Length | 475-870mm |

| Bottom Size | 80-120mm |

| Bottom Center Distance | 375~750mm |

| Valve Sticker Width | 170~260mm |

| Valve Sticker Length | 80~200mm |

| Outside Patch Width | 80~120mm |

| Outside Patch Length | 300-500mm |

| Production Speed | 120pcs/min |

| Total Power | 150kw |

| Total Weight | Approx. 16000kg |

| Overall Dimension | L11000 xW7500x H2500mm |

Popular Science: Comparison of the characteristics of PP valve bags and PE valve bags

PP Valve Bags vs. PE Valve Bags

Shared Advantages

✅ Eco-friendly: Glue-free heat sealing, recyclable

✅ Durable: Moisture/dust/antistatic protection, corrosion-resistant

✅ Efficient: Auto-fill compatible, leak-proof

Key Differences

| Feature | PP Valve Bags | PE Valve Bags |

|---|---|---|

| Material | Polypropylene (lightweight, tough) | Polyethylene (flexible, dense) |

| Print Quality | Clear & vivid | Smoother, premium finish |

| Extra Functions | — | Custom antiskid patterns for stable stacking |

| Cost | Lower | Slightly higher (advanced tech) |

| Ideal For | Industrial products (fertilizers, feed, cement, etc.) | High-standard fields (food/pharma/high-precision chemicals) |

Quick Selection Guide

Choose PP: Cost-effective for industrial use

Choose PE: Premium printing + antiskid needs

This machine is an ideal machine for printing paper cup, carton, paper bag and so on.lt is controlled centrally by PLC s...

This machine is mainly used to produce various sized paper sacks by taking paper or paper+film tubes as raw materials, w...

This machine is mainly used to produce various sized sack tube (step-type and straight-type) by taking roll paper and PE...

1. IntroductionToday, environmental consciousness is no longer just a trend—it’s a core consideration for both consumers...

A detailed guide to the industrial paper bag manufacturing process, from raw material preparation and printing to automa...

When it comes to purchasing valve bag making machines for building materials, what truly matters to buyers is one thing:...

GET A QUOTE