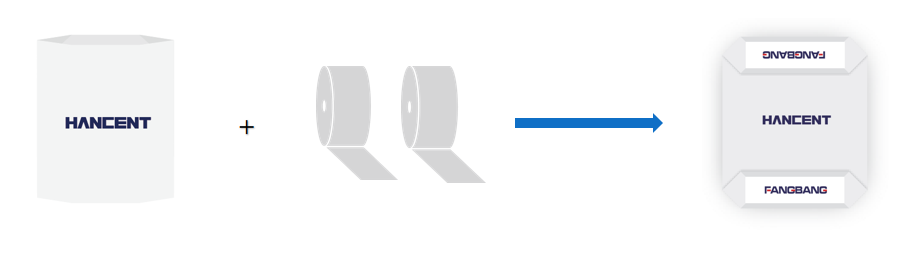

This Multi-Function Paper Sack Manufacturing System specializes in manufacturing precision-engineered paper sacks across diverse dimensions, utilizing either pure paper or composite paper-film tubing as base materials. Designed for seamless integration with valve sack tuber equipment, the system executes 10 critical production stages through synchronized automation:

✓Precision tube feeding

✓Bottom section formation

✓Internal valve application

✓ External valve integration

✓Reinforcement patch installation

✓Adhesive application system

✓External protective patching

✓ Bottom sealing mechanism

✓Pressure-bonding process

✓Automated sack collection

Key Operational Advantages:

- Reduces labor requirements by up to 70% through integrated automation

- Maintains a ±1.5mm dimensional accuracy error after bottom folding.

- Incorporates real-time defect detection with 99.2% rejection accuracy

- Processes 80~220pcs/min sacks/hour (varies by material/size)

Quality Assurance Features:

* PLC-controlled tension management system

* Multi-stage adhesive curing verification

* Automatic jam prevention protocol

* Energy-saving servo motor configuration

* ISO 9001-compliant production standards

This system integrates German-engineered mechanical components with Japanese precision sensors, ensuring high operational uptime in continuous production environments. Optional configurations are available for humidity-controlled environments and explosive material handling applications.

| TECHNICAL DATA | HD-2625NEW |

| Tube Width | 350~700mm |

| Tube Length | 470~1300mm |

| Bottom Width | 90~250mm |

| Bottom Center Distance | 260~1200mm |

| Glue Supplying Mode | Closed Glue Box,Automatic Glue Supplying |

| Valve type | Common Internal Vake, Paper+Fiim Inside Valve,(thumb) Outside Vakve and Uitrasonic Valve |

| Valve Paper Thickness | 80~120g/m |

| Error of Valve Misalignment | ±2.5mm |

| Error after Bottom Folding | ±1.5mm |

| Production Speed | 80~220pcs/min |

| Total Power | 75kw |

| Total Weight | Approx. 65000kg |

| Overall Dimension | L35000xW4000xH3950mm |

Versatile Applications of Valve Bags

Valve bags, characterized by their unique spout-like opening and self-sealing design, are widely used across industries due to their durability, efficiency, and adaptability. Below are key sectors where valve bags excel, along with their specific applications:

✅Agriculture & Fertilizers

Valve bags are ideal for storing and transporting bulk agricultural products.

Seeds & Grains: Protect seeds from moisture and pests.

Fertilizers: Prevent leakage of powdered or granular fertilizers.

Animal Feed: Ensure hygienic storage and easy dispensing.

✅Building Materials

Their robust structure makes valve bags perfect for heavy-duty materials.

Cement & Concrete Mix: Dust-tight design minimizes product loss.

Gypsum & Plaster: Maintain dryness and prevent clumping.

Sand & Aggregates: Facilitate controlled pouring on construction sites.

✅Chemicals & Industrial Products

Valve bags offer safety and precision for hazardous or sensitive materials.

Powdered Chemicals: Reduce exposure risks during handling.

Dyes & Pigments: Prevent contamination and color cross-mixing.

Mineral Ores: Enable secure transport of fine particles.

✅Food & Beverage Industry

Designed to meet hygiene standards, valve bags are critical for food-grade storage.

Flour & Sugar: Preserve freshness and prevent spillage.

Spices & Additives: Block external odors and moisture.

Coffee Beans & Cocoa: Maintain aroma and quality during shipping.

✅Environmental & Recycling

Valve bags support eco-friendly initiatives.

Recyclable Plastics: Store shredded materials efficiently.

Biodegradable Waste: Simplify collection and transportation.

Wood Pellets: Optimize bulk handling for biomass energy production.

✅Pharmaceuticals

Precision and cleanliness are ensured for medical applications.

Powdered Medications: Minimize contamination risks.

Laboratory Reagents: Protect sensitive compounds from humidity.

Herbal Extracts: Preserve potency during storage.

✅Retail & Consumer Goods

Valve bags enhance convenience for end-users.

Pet Litter: Easy-to-pour design for mess-free usage.

Charcoal & Firelighters: Reduce dust emission during handling.

DIY Products: Simplify storage of grout, mortar, or gardening supplies.

✅Logistics & Transportation

Their stackable design optimizes space and reduces costs.

Automated Filling: Compatible with high-speed packaging lines.

Palletization: Enable stable stacking for long-distance shipping.

Custom Branding: Print logos or instructions for marketing versatility.

From agriculture to pharmaceuticals, valve bags provide a reliable, cost-effective solution for diverse industries. Their adaptability to automated systems, combined with superior product protection, ensures they remain a cornerstone of modern bulk packaging.

This machine produces square bottom plastic sacks with valves by taking double-sided coated polypropylene tube as raw ma...

This machine is mainly used to produce various sized sack tube (step-type and straight-type) by taking roll paper and PE...

This machine derives from the traditional roll-fed paper bag machine by adding special function, which makes itself be a...

A detailed guide to the industrial paper bag manufacturing process, from raw material preparation and printing to automa...

When it comes to purchasing valve bag making machines for building materials, what truly matters to buyers is one thing:...

If you've ever grabbed a crisp shopping bag from a retail store, a sturdy carry-out bag from a restaurant, or a beautifu...

GET A QUOTE