Industrial production of paper bags is a systematic and efficient process. The specific steps vary depending on the bag type, but the core process remains consistent. Below is a step-by-step guide to machine-made paper bag production suitable for large-scale manufacturing.

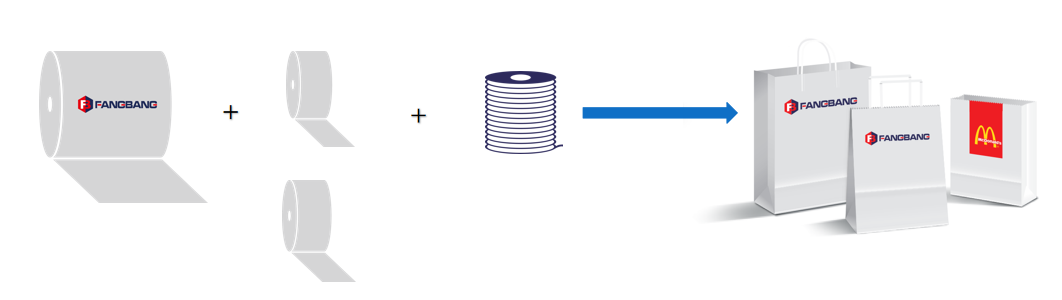

Step 1: Raw Material Preparation

The core material is roll paper, commonly made from kraft paper, white cardboard, and recycled paper. Depending on the required bag strength, the paper weight typically ranges from 80 to 250 grams per square meter.

This step requires a slitting machine. Large rolls of paper are unwound and cut into smaller rolls or sheets of specific widths and lengths according to the predetermined bag dimensions. The key is to ensure uniform cutting, avoiding dimensional errors, while adjusting tension to prevent paper wrinkling.

Step 2: Printing and Design

For paper bags that need to display brand logos, patterns, or product information, printing is a necessary pre-processing step. Flexo Printing Machines are most commonly used due to their cost-effectiveness and suitability for high-speed production. For orders requiring extremely high color accuracy and durability, gravure printing machines are used.

During operation, the customized printing plates are installed on the machine, and the slit paper rolls are fed in. Environmentally friendly water-based ink is transferred to the paper surface via the printing plates, and then the ink is cured using a hot air or infrared drying system to prevent smudging. The key is to match the ink to the paper and control the printing speed and pressure to ensure clear patterns and consistent colors.

Step 3: Bag Forming

This step transforms the printed or blank paper into bag blanks. Based on the level of automation, there are two main production modes.

Semi-automatic Paper Bag Machines are suitable for small-batch or customized production. First, a creasing and folding machine is used to create clear fold lines on the paper and fold it into the basic shape of the bag body. Subsequently, a gluing and sealing machine applies hot melt adhesive or water-based adhesive to the bottom flap, which is then pressed to form a secure bottom seal.

Fully automatic production lines are suitable for large-scale, standardized production. Automatic bag-making machines integrate all forming steps, achieving one-stop processing. The machine automatically unwinds and feeds the paper, sequentially completing creasing, edge folding, and bottom forming, followed by high-speed gluing and pressing to seal the bottom, and finally cutting the continuous bag tube into individual bag blanks. For bag types requiring a self-standing base, the machine can simultaneously complete the formation of the bottom structure in this step.

Step 4: Handle Installation

Shopping bags, gift bags, and other bags with handles require the additional step of handle installation. Depending on the handle type, equipment such as punching machines, stringing machines, or automatic handle attachment machines will be used.

Paper handles are typically made by cutting paper strips, punching holes in the bag body, and then inserting and gluing the strips in place. Rope handles use cotton, plastic, or paper ropes, with the machine performing the punching and threading, and using adhesive or metal fasteners to secure the ends of the rope. The key is to ensure the handles are securely attached, can withstand the rated weight, and that the hole positions are precisely controlled to maintain product aesthetics.

Step 5: Quality Inspection and Finishing

This stage combines visual inspection machines with manual sampling. Main inspection items include printing defects such as smudging, color differences, or missing patterns; checking bag dimensions, bottom seal strength, and handle security. If necessary, a trimming machine will be used to trim irregular edges or remove excess glue.

Step 6: Counting and Packaging

An automatic counting and stacking machine counts and neatly stacks the qualified paper bags. A packaging machine then wraps the stacks of paper bags in plastic film or packs them into cardboard boxes for bulk transportation to prevent moisture damage and breakage.

Key Technical Points of Automated Production

Paper Adaptability: Machine parameters, including speed, pressure, and temperature, must be adjusted according to the paper weight and thickness to avoid tearing or deformation of the paper.

Adhesive Control: If hot-melt adhesive is used, the temperature is usually controlled between 160°C and 180°C to ensure bonding strength without damaging the paper.

High-Speed Production Coordination: Fully automated production lines can reach speeds of 300 to 600 paper bags per minute, requiring coordinated operation of all modules to avoid production bottlenecks.