During this period, China's printing and packaging industry was extremely low in automation and relied heavily on manual operations. At the age of 18, Mr. Fang Jianshe, then a mechanical engineer, joined the state-owned enterprise Shangwang Irrigation & Drainage Station (later renamed Shangwang Printing Machinery), which mainly produced various types of printing machines. During his tenure there, he studied diligently for this career—a career he would dedicate his entire life to.

Driven by the government's reform and opening-up policy, Mr. Fang Jianshe resigned from Shangwang Printing Machinery and founded Ruian County Shangwang Machinery Equipment Co., Ltd., where he served as factory director and which mainly produced square-box printing machines, offset printing machines and other products.

In order to meet the needs of large-scale socialized production driven by the market economy, Mr. Fang Jianshe founded Ruian Jianshe Printing Machinery Co., Ltd. and served as its chairman. The company mainly produced gravure printing machines, three-side sealing bag making machines, dry laminating machines and slitting machines, and in the same year, its gravure printing machines were successfully exported to Vietnam for the first time.

With the continuous upgrading of products, Mr. Fang Jianshe founded Ruian Jianshe Packaging Equipment Co., Ltd., which mainly produced computer gravure printing machines and other packaging machinery. With the expansion of its business scale, the company was restructured and renamed Zhejiang Fangbang Machinery Co., Ltd. in 2002.

With his foresighted business vision and keen market insight, Mr. Fang Jianshe insisted on innovation and continuously developed new products. To build a global sales system, he set up sales teams for both domestic and foreign markets and led these teams to participate in numerous domestic and foreign printing and packaging exhibitions.

After visiting the Tokyo Pack exhibition in Japan, Mr. Fang Jianshe predicted that paper bags would become the mainstream environmentally friendly packaging in the world in the near future. After careful consideration, he decided to establish a dedicated R&D team for paper bag machines. Subsequently, in December, he founded Jiangsu Fangbang Machinery Co., Ltd. in Suzhou City.

As an undergraduate, Jessica Fang accompanied her father Mr. Fang Jianshe to Drupa 2008 in Germany for the first time—an experience that laid a solid foundation for Fangbang Group’s foreign trade development. In June of the same year, China issued the nationwide Plastic Restriction Order for the first time. In August, Kevin Fang enrolled at the National University of Singapore from Zhejiang University on a full scholarship. Meanwhile, recognizing the technological gap in printing and packaging machinery between China and European and American countries, Mr. Fang Jianshe strengthened his conviction that "A craftsman of a great country always prioritizes quality first".

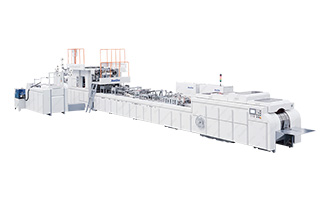

With the gradual enhancement of people's awareness of environmental protection and the continuous development of emerging technology applications, Fangbang has always adhered to the principle of "environmentally friendly manufacturing". Its products, including paper bag machines and flexo printing machines, began to capture domestic and foreign markets quickly, which met customers' various requirements for environmentally friendly printing and packaging equipment.

Kevin Fang went to Germany to participate in the global exhibition Drupa 2012, and upon his return to China, he officially joined Fangbang Group as general manager. He also appointed Jessica Fang as director of foreign trade. In October, Jiangsu Fangbang was recognized as an "Enterprise Technology Center" by the Suzhou Municipal Government.

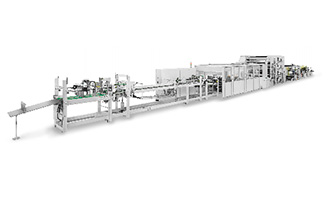

As the sales scale of flexo printing machines expanded, Fangbang Group established Wenzhou Flex Machinery Co., Ltd., dedicated to flexographic printing business. In August, Jiangsu Fangbang’s Fully Automatic Sheet-fed Square Bottom Paper Bag Machine won the award "Jiangsu Province's First Set of Major Equipment and Key Components". In October, Jiangsu Fangbang was awarded the title of "High-tech Enterprise" in Jiangsu Province for the first time.

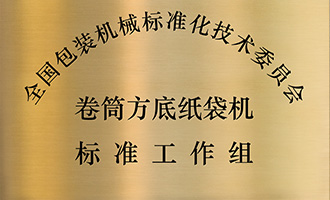

Jiangsu Fangbang formulated the national standard GB/T 36238-2018 "General Specification for Roll-fed Square Bottom Paper Bag Machine" and was admitted to the standard working group of the National Packaging Machinery Standardization Technical Committee (TC436). In August, in response to Wenzhou’s merchant return policy , Jiangsu Fangbang established Zhejiang Hancent Technology Co., Ltd. as a wholly-owned subsidiary and began to develop valve bag making machines .

Jiangsu Fangbang was awarded the title of Suzhou "Gazelle Enterprise", and was re-elected as a Director Unit of the China Printing and Equipment Industry Association in November of the same year.

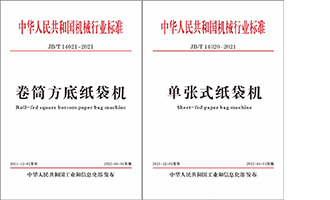

As the drafting unit, Jiangsu Fangbang formulated the industry standards JB/T 14021-2021 "Roll-fed Square Bottom Paper Bag Machine" and JB/T 14020-2021 "Sheet-fed Square Bottom Paper Bag Machine". In August, Fangbang Group officially launched the valve sack tuber and valve sack bottomer to the market.

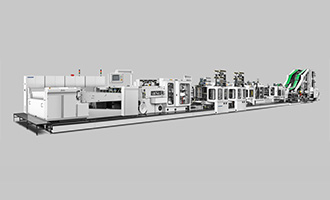

Fangbang Group’s new production base—the intelligent modern factory of Zhejiang Hancent, with a construction area of over 100,000 m²—was officially put into use. Its main products cover paper bag machines, valve bag machines and flexo printing machines, providing customers around the world with the highest-quality printing and packaging production solutions. In the same year, the high-speed valve sack tuber produced by Zhejiang Hancent was successfully launched to the market.

GET A QUOTE