If you're sourcing packaging machinery to capitalize on the global shift away from plastic, you've likely pinpointed the need for reliable, high-volume production. The most strategic investment to achieve this is a robust paper carry bag making machine from China. This equipment transforms rolls of kraft paper into finished, market-ready bags with handles, offering an unbeatable combination of scalability, cost-efficiency, and compliance with evolving environmental regulations. In this expert guide, we'll explore the operational mechanics, tangible benefits, and critical reasons why selecting a premier Chinese brand like FANGBANG can future-proof your business, backed by authoritative data and actionable insights tailored to serious buyers.

Understanding the Mechanics of a Modern Paper Bag Manufacturing Machine

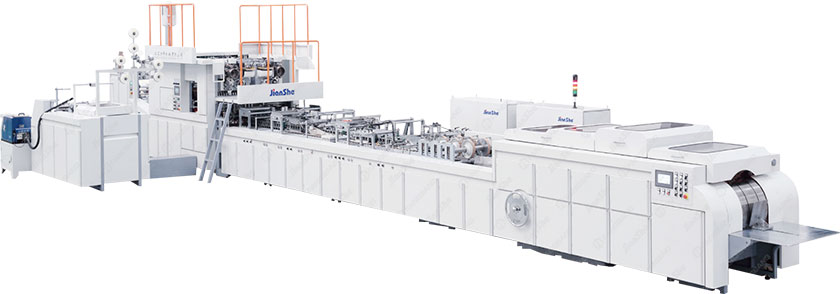

A paper carry bag making machine is an integrated system designed to automate the entire process of creating shopping bags, from flat paper reels to the final packaged product. The process typically involves unwinding, handle drawing and pasting, bottom folding and sealing, and final pressing and counting. The driving force behind this market is undeniable. According to a Smithers report, the global demand for paper packaging is projected to reach $400 billion by 2025, with paper bags representing one of the fastest-growing segments due to stringent plastic bans worldwide. For a business owner or investor, this translates to a critical juncture: secure a dependable paper bag production line or risk being unable to meet market demand. A high-performance automatic paper bag machine from a manufacturer like FANGBANG directly addresses core buyer pain points—namely, reducing labor costs by up to 60%, minimizing material waste through precision engineering, and ensuring a consistent, high-quality product that strengthens your brand's reputation for quality and sustainability.

Why Sourcing a Paper Carry Bag Making Machine from China is a Strategic Advantage

Procuring your paper carry bag making machine from China is not merely about cost savings; it's about accessing a mature ecosystem of innovation and manufacturing excellence. Chinese manufacturers like FANGBANG have honed their engineering and production processes over decades, allowing them to offer machines that provide an exceptional balance of performance, durability, and value. While the initial purchase price is often significantly lower than European or American counterparts, the true advantage lies in the total cost of ownership. Consider a garment distributor in Europe: by investing in a FANGBANG machine, they cut their bag procurement costs by half within 18 months, while also gaining the agility to produce custom bags for special collections without relying on external suppliers with long lead times. Furthermore, China's vast industrial supply chain means that replacement parts and technical support are readily available, minimizing potential downtime. This strategic advantage empowers you to build a more resilient and self-sufficient supply chain.

Key Features of a High-Speed Automatic Paper Bag Machine

When evaluating equipment, the specifications of a high-speed automatic paper bag machine are paramount to your profitability. The core of this machinery lies in its handling system and sealing technology. A modern FANGBANG machine can produce between 40 to 80 bags per minute, a throughput that allows a single medium-sized facility to service multiple retail chains simultaneously. Key features to prioritize include a PLC control system for easy operation and troubleshooting, servo motor-driven precision for consistent glue application and fold accuracy, and quick-change mechanisms that allow for switching bag sizes in under 15 minutes. This operational efficiency is a direct response to buyer needs for flexibility and reduced changeover waste. For instance, a FANGBANG client in the food delivery sector reported a 30% increase in overall productivity due to the machine's stability and user-friendly interface, enabling them to meet tight deadlines for large QSR (Quick Service Restaurant) contracts.

FANGBANG’s Engineering Excellence: Reliability in Paper Bag Production Equipment

The FANGBANG brand has become synonymous with reliability in the paper bag machine sector. Their equipment is engineered for 24/7 operation in demanding industrial environments. Critical components, such as the main frame and forming heads, are constructed from reinforced materials and undergo rigorous quality control, directly impacting the machine's lifespan and production stability. FANGBANG integrates advanced energy-saving technology, with some models reducing power consumption by up to 25% compared to previous generations, a critical factor as energy costs rise globally. A case study from a Latin American packaging converter demonstrated that their FANGBANG paper bag manufacturing line maintained an uptime of over 96% across three shifts for two consecutive years, a testament to its robust design. This unwavering reliability means you can confidently plan your production schedules and honor large contracts without the constant fear of mechanical failure.

Customized Paper Bag Production Line Solutions for Your Specific Needs

The one-size-fits-all approach is obsolete in today's competitive market. FANGBANG excels in delivering customized paper bag production line solutions tailored to unique business requirements. Whether you need to produce standard grocery bags, premium retail bags with twisted paper handles, or bakery bags with special window patches, the machine's configuration can be adapted. Imagine a large bookstore chain wanting to launch a city-wide promotional campaign with uniquely printed, sturdy carry bags. With a FANGBANG machine equipped with an in-line flexographic printing unit and reinforced handle attachment, they can produce these branded bags on-demand, controlling inventory and marketing messaging in real-time. This customization extends to the raw material; FANGBANG machines can handle a wide range of paper grades, including recycled and FSC-certified kraft paper, allowing you to cater to the growing consumer demand for sustainable products. From initial consultation to factory layout planning, FANGBANG provides end-to-end support to ensure your paper bag making operation is optimized for success from day one.

Navigating Your Investment: Data and ROI for Paper Bag Machinery

A capital investment of this scale requires a clear-eyed view of the financials. The market for paper carry bag making machines is buoyant, supported by data from Research and Markets which forecasts the flexible paper packaging market to grow at a CAGR of 4.2% through 2027. When analyzing the Return on Investment (ROI), key metrics include production output, labor savings, and material utilization. A well-optimized FANGBANG automatic bag making system can achieve an overall equipment effectiveness (OEE) rating of over 85%, placing it in the world-class category for discrete manufacturing. Financial models often show that for a medium-volume producer, the initial investment in a Chinese-made machine can be recouped in as little as 12-20 months through the combined effect of reduced external procurement costs and increased sales capacity. By focusing on these data-driven insights, you can build a solid business case that positions the paper carry bag making machine not as an expense, but as a profit center that drives long-term growth.

Implementing Your Machine: From Setup to Sustainable Production

The final, crucial step is the seamless integration of your new paper carry bag making machine into your production workflow. This begins with thorough pre-delivery planning, ensuring your facility meets the requirements for power, compressed air, and floor space. FANGBANG mitigates implementation risks by providing comprehensive services, including supervised installation, detailed operator training, and a clear preventative maintenance schedule. A typical rollout involves a commissioning period where machine settings are fine-tuned for your specific paper stock, followed by a ramp-up phase to build operator competency. Adherence to the maintenance schedule is critical; data from the Plant Engineering and Maintenance Association indicates that proactive maintenance can reduce machine downtime by up to 50%. By leveraging FANGBANG's global service network and following their operational guidelines, you can ensure your paper bag production line becomes a model of efficiency and sustainability, producing the eco-friendly packaging that the modern market demands.

Ready to transform your packaging capabilities and lead the shift to sustainable solutions? Discover the full range of high-performance paper carry bag making machines from FANGBANG. Contact our engineering team today for a free, no-obligation consultation and a customized production solution tailored to your business goals.

This article was created with AI assistance to ensure data accuracy and comprehensive coverage.