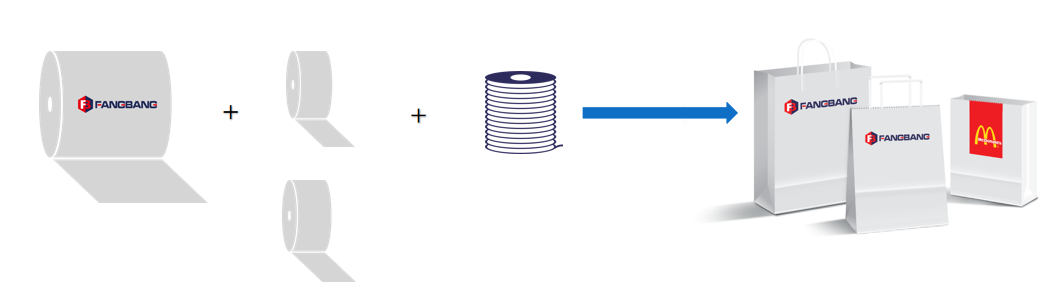

This Full-Servo Automatic Square Bottom Paper Bag Machine uses rolled paper, rolled header card, and paper rope as raw materials. One-time completion of square-bottom paper bags with handles is the ideal equipment for the rapid production of hand-held paper bags.

Fully Automated Production: The machine completes handle making, handle gluing, paper tube forming, paper tube cutting, and bag bottom forming in a single process, realizing fully automated production and effectively reducing labor costs.

Precise Cutting: The photoelectric eye system automatically adjusts the cutting length, ensuring accurate cutting and maintaining consistent precision.

Stable and Fast Operation: Featuring a Siemens PLC system and an adjustable double template structure, the machine guarantees quick and stable operation while minimizing the time required for size adjustments.

Improved Efficiency: The specially designed bag collecting platform, combined with the counting function, enhances the efficiency of batch packing finished products.

High-Speed Production: Thanks to its excellent craftsmanship and fast bag-making speed, the machine significantly boosts overall production efficiency.

This paper bag-making machine is ideally suited for the high-volume production of various paper bags, including paper compost bags, paper favor bags, paper party bags, supermarket paper bags, and food paper bags. Its advanced capabilities make it particularly efficient for mass production in industries such as food and garments, ensuring fast, reliable output to meet growing market demand.

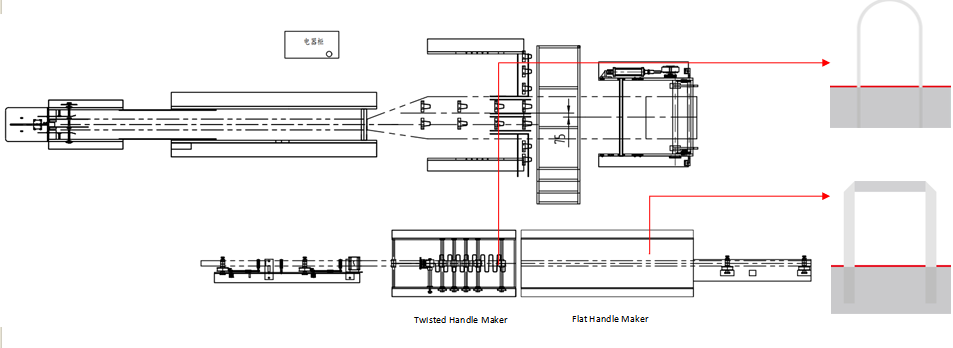

| Versatile Bag Mouth Cutting: With one machine, the bag mouth can be cut into either a toothed or flat shape, offering two distinct appearances. |  |

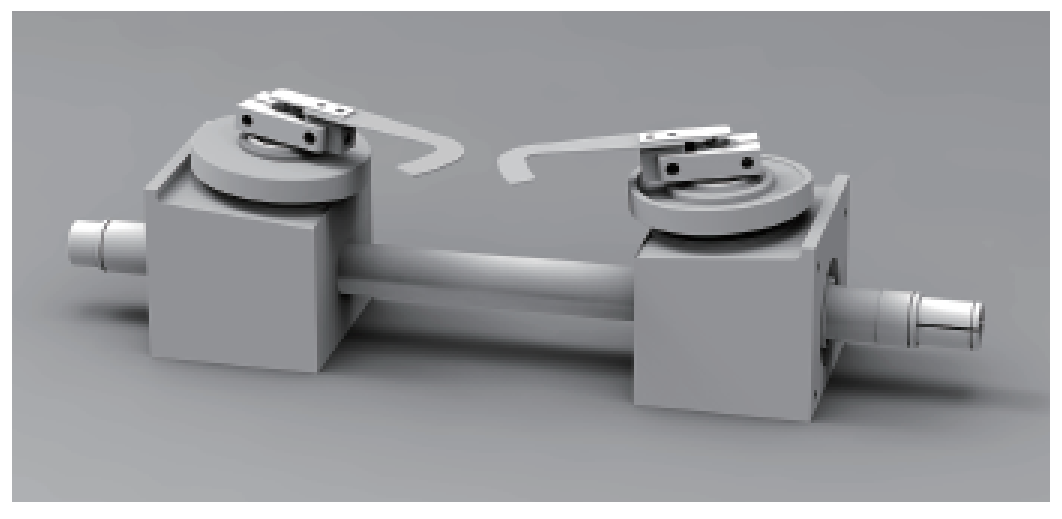

| Dual-Handle Capability: This machine can be equipped with both round rope and flat rope handles, allowing for versatile production of both round and flat bags. |  |

|

The ZD-QFJ08T model is designed to produce single cup coffee take-away bags, ideal for serving individual coffee orders. The ZD-QFJ13 model is capable of producing double cup coffee paper take out bags, offering a practical solution for carrying two cups of coffee at once, perfect for customers who want more convenience. |

|

| The handles for paper bags can be conveniently attached either to the inside or the outside of the bag, depending on your preference. This flexibility allows for customization in design, especially for paper gift bags with handles, ensuring both functionality and aesthetic appeal. |  |

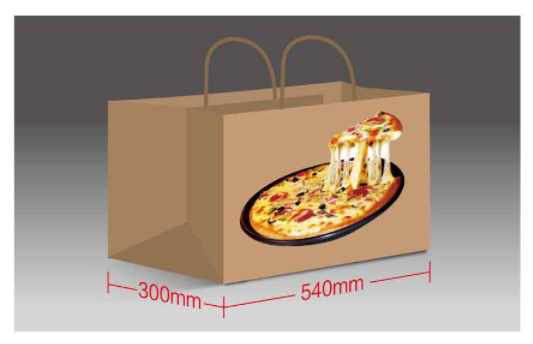

| The ZD-QFJ21M model is highly versatile, capable of producing paper pizza bags with a bottom width of up to 300mm. This flexibility allows it to accommodate various sizes, making it ideal for producing bags tailored to different products and packaging needs. |  |

| TECHNICAL DATA | ZD-QFJ08C[F] | ZD-QFJ08[N] | ZD-QFJ11E | ZD-QFJ13E[S] | ZD-QFJ14[S] | ZD-QFJ18P | ZD-QFJ21S[M] |

| Paper Roll Width | 370-630mm | 410-770mm[380-770mm | 590-890mm(370-890mm) | 590-990mm(400-990mm) | 590~1150mm | 670-1390mm(590-1390mm) | 630-1530mm[690-1710mm] |

| Max. Paper Roll Diameter | Ф1500mm | Ф1500mm | Ф1500mm | Ф1500mm | Ф1500mm | Ф1500mm | Ф1500mm |

| Material Core Diameter | Ф76mm(3") | Ф76mm(3”) | Ф76mm(3”) | Ф76mm(3") | Ф76mm(3") | Ф76mm(3”) | Ф76mm(3") |

| Paper Thickness | 45-140/㎡ | 50-140g/m* | 50-150g/㎡ | 80-160g/㎡ | 80-150g/㎡ | 70-160g/㎡ | 80-170g/m |

| Bag Body Width | 120-200mm | 140-220mm[120-220mm | 200-280mm(110-280mm) | 200-330mm(125-330mm) | 200-360mm | 240-460mm(200-460mm) | 220-540mm |

| Paper Tube Length | 190-370mm(190-430mm) | 215-370mm(215-470mm) | 270-410mm(270-530mm) | 270-420mm(270-530mm) | 350-550mm(350-650mm) | 350-520mm(280-620mm) | 380-650mm(380-770mm) |

| Bag Bottom Size | 50-100mm | 50-140mm | 60-150mm | 60-150mm[70-180mm] | 80-200mm[100-230mm] | 80-220mm | 80-254mm[110-300mm] |

| Handle Rope Height | 90-95mm | 80mm~85mm[90-95mm] | 110-115mm | 110~115mm | 110-115mm | 110-115mm | 110-115mm |

| Handle Rope Diameter | Ф3-4mm | Ф4-6mm[Ф3-4mm] | Ф4-中6mm | Ф4-6mm | Ф4-Ф6mm | Ф4-6mm | Ф4-6mm |

| Handle Patch L .ength | 96mm | 114.3mm[96mm] | 152.4mm | 152.4mm | 152.4mm | 190.5mm | 190.5mm |

| Handle Patch Width | 45~50mm | 45~50mm | 45-50mm | 45~50mm | 45~50mm | 45-50mm | 45-50mm |

| Paper Patch Roll Diameter | Ф1200mm | Ф1200mm | Ф1200mm | Ф1200mm | Ф1200mm | Ф1200mm | Ф1200mm |

| Paper Patch Roll Width | 90-100mm | 90-100mm | 90-100mm | 90-100mm | 90~100mm | 90~100mm | 90-100mm |

| Paper Patch Thickness | 100~180g/㎡ | 100~180g/㎡ | 100~180g/㎡ | 100~180g/㎡ | 100-180g/㎡ | 100-180g/㎡ | 100-180g/m2 |

| Max. Speed | 200bags/min(220bags/min) | 200bags/mi(220bags/min) | 180bags/mi(220bags/min) | 180bags/min(220bags/min) | 160bags/min(150bags/min) | 180bags/min(180bags/min) | 110bags/min(120bags/min) |

| Total Power | 28kw | 28kw | 38kw | 38kw | 39kw | 38kw | 39kw[44kw] |

| Total Weight | Approx.15000kg | Approx. 15000kg | Approx.18000kg | Approx.18000kg | Approx.20000kg | Approx. 20000kg | Approx. 23000kg |

| Overall Dimension | L11000xW4400xH1800mm | L11000xW4400xH1800mm | L14000xW6000xH3400mm | L14000xW6000xH3400mm | L14000xW6000xH3400mm | L14500xW6000xH3400mm | L14000xW6000xH3400mm |

|

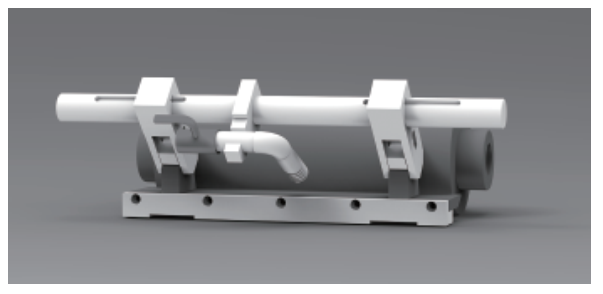

ZD-QFJ08 adopts a special bottom closing device. |

|

|

New and innovative automatic priming system (water-based glue). |

|

Fully Automatic Sheet-Fed Square Bottom Paper Bag Machine produces paper bags with handles at high speed. Uses sheet pap...

This machine is designed to manufacture square bottom paper bags with flat-rope handles from paper roll,paper patch roll...

1. IntroductionToday, environmental consciousness is no longer just a trend—it’s a core consideration for both consumers...

A detailed guide to the industrial paper bag manufacturing process, from raw material preparation and printing to automa...

When it comes to purchasing valve bag making machines for building materials, what truly matters to buyers is one thing:...

GET A QUOTE