Paper Bag Manufacturing Machine Price

If you've landed here, your primary question is straightforward: "What is the paper bag manufacturing machine price?" The direct answer is, it's not a single figure. The investment can range from a manageable $20,000 for a basic, semi-automatic setup to a significant $500,000+ for a high-speed, fully-integrated production line. The final cost hinges entirely on your specific business goals, production targets, and the types of bags you intend to manufacture. This comprehensive guide is designed to demystify that price tag, moving beyond a simple number to explore the value, components, and long-term return on investment that a machine from an industry leader like Fangbang can deliver. We will dissect the factors that influence cost, helping you make an informed financial decision for your packaging business.

Understanding the Spectrum: What Dictates Paper Bag Machine Pricing?

Walking onto a factory floor, the hum of machinery is the sound of productivity. But before that sound begins, a critical capital expenditure decision must be made. The paper bag manufacturing machine price is a composite of several engineering and commercial factors. It's less about buying a commodity and more about investing in a production capability.

First and foremost is the level of automation. A semi-automatic paper bag machine requires more hands-on operation for tasks like handle punching and gluing, making it a lower initial investment, ideal for startups or small batch productions. Conversely, a fully automatic paper bag making machine is a marvel of modern engineering, handling everything from paper roll feeding to bottom sealing, handle application, and counting with minimal human intervention. This efficiency and high output come with a higher price tag but offer a lower cost-per-bag in the long run.

The second major cost driver is the bag type and complexity. A simple paper bag machine producing flat-bottomed grocery bags without handles is at one end of the spectrum. The moment you introduce elements like handle making (especially for twisted-paper handles), gusseting, complex window patching, or printing capabilities (via an integrated flexographic printer), the machine's complexity and cost increase substantially. A bottom pasting paper bag machine designed for robust shopping bags is a different beast altogether from one making simple merchandise bags.

A Detailed Breakdown of Paper Bag Making Machine Cost Ranges

Let's put some tangible numbers to the theory. Please treat these figures as informed estimates; a precise quote from Fangbang will be tailored to your needs.

-

Entry-Level & Semi-Automatic Machines ($20,000 - $70,000): This range is typically for small scale paper bag machine setups. These machines are often slower, with production speeds under 100 bags per minute. They are perfect for niche markets, custom boutiques, or businesses testing the waters of paper bag production. The investment is lower, but the labor cost per unit is higher.

-

Mid-Range Fully Automatic Machines ($70,000 - $200,000): This is the sweet spot for many established paper bag manufacturers. Here, you find robust, fully automatic machines capable of producing a wide variety of bag styles, including bags with handles, at speeds ranging from 100 to 200 bags per minute. This category often includes machines with basic flexographic printing units for single or two-color logos, adding significant value.

-

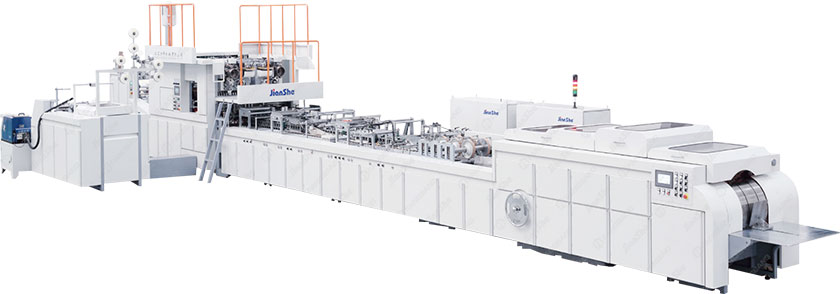

High-Speed, Integrated Production Lines ($200,000 - $500,000+): For large-scale paper bag manufacturing businesses supplying major retail chains, the paper bag machine cost enters this tier. These are not just machines; they are integrated systems. They feature ultra-high speeds (250+ bags/minute), advanced in-line printing with CI (Central Impression) cylinders for high-quality graphics, sophisticated handle attachment systems, and automated quality control with vision systems. The ROI is calculated on a massive volume scale.

Beyond the Sticker Price: The Real Cost of Ownership and Operation

A savvy buyer looks beyond the initial invoice. The true paper bag manufacturing machine price includes the Total Cost of Ownership (TCO).

-

Installation & Training: A complex machine requires expert installation and comprehensive operator training. Fangbang includes this as part of our service, ensuring your team is confident and productive from day one.

-

Maintenance & Spare Parts: Regular maintenance is non-negotiable. The quality of the machine's components, like the paper bag making handle punch, directly impacts downtime. Fangbang machines are built with durability in mind, and our global spare parts network ensures you're never waiting long for a critical component.

-

Energy Consumption: Modern, servo-driven machines are far more energy-efficient than their older counterparts. This is a hidden but significant operational cost over years of use.

-

Raw Material Versatility: Can the machine efficiently run on different grades of paper, including recycled content? A machine that can adapt to material price fluctuations provides long-term financial stability.

Calculating Your ROI: When Will the Machine Pay for Itself?

This is the most crucial question for any paper bag manufacturing business owner. The Return on Investment is not just about the paper bag machine price; it's about the profit it generates.

A simple ROI calculation involves:

(Annual Profit Generated by the Machine / Total Machine Investment) * 100 = ROI %

The "Annual Profit" is influenced by:

-

Production Output (Bags Per Minute): Higher speed machines fill more orders.

-

Labor Cost Reduction: Fully automatic systems drastically reduce the number of operators required per thousand bags.

-

Reduced Reject Rate: Precision engineering from Fangbang means fewer wasted materials due to manufacturing defects.

-

Ability to Command Higher Prices: Producing high-quality, complex bags with excellent print quality allows you to target premium markets.

For example, a Fangbang machine that enables you to produce 5 million high-value, handled bags per year for a key client can pay for itself in a surprisingly short timeframe, often between 18 to 36 months.

Why Fangbang Machines Offer Superior Value at a Competitive Price

When you partner with Fangbang, you are not just purchasing a machine; you are investing in a partnership. Our paper bag manufacturing machine price is structured to deliver unparalleled value, blending robust engineering with intelligent service.

-

Proven Durability & Low Maintenance: Our machines are built with high-precision components and hardened steels for critical parts like the handle making unit, ensuring they withstand 24/7 operation with minimal wear and tear.

-

Customization is Our Standard: We understand that your needs are unique. Whether you need a specialized bottom pasting system for extra-strong bags or a unique handle attachment mechanism, we engineer solutions, not just sell standard models.

-

Unmatched Technical Support & Training: Our global team of engineers provides remote diagnostics and on-site support. We ensure your operators are masters of the machinery, maximizing uptime and efficiency.

-

Focus on Your Bottom Line: Every Fangbang machine is designed with operational economy in mind, from quick changeover times to reduce downtime between orders to energy-saving servo motors that cut your power bills.

Navigating the Purchase Process: From Inquiry to Installation

Knowing the paper bag machine cost is one thing; navigating the purchase is another. Here’s a clear pathway with Fangbang:

-

Initial Consultation: You discuss your business goals, target market, bag types, and desired output with our experts.

-

Machine Recommendation & Quotation: We provide a detailed proposal outlining the perfect machine for your needs, with a transparent paper bag manufacturing machine price and delivery timeline.

-

Factory Acceptance Test (Optional): You are welcome to visit our facility or witness a live video test of your machine before shipment, verifying its performance.

-

Shipping & Installation: We manage the logistics and send our engineers to your site for installation and commissioning.

-

Comprehensive Training & Handover: We train your team until they are fully confident in operating the machine safely and efficiently.

-

Ongoing Support: Our relationship continues with lifelong spare parts supply and technical support.

Ready to Get a Precise, Custom Quote?

Stop searching for a vague "paper bag manufacturing machine price". The real value lies in a solution tailored to your ambition. Fangbang is committed to being more than a vendor; we are your strategic partner in building a profitable and sustainable packaging business.

Contact our specialist team today for a no-obligation consultation and a detailed quotation. Let's calculate the real ROI for your business.

Click Here to Explore Our Paper Bag Machine Models and Contact Us

This article was crafted with the assistance of artificial intelligence to ensure data comprehensiveness and was subsequently refined and validated by our human packaging machinery experts at Fangbang to guarantee accuracy and relevance.