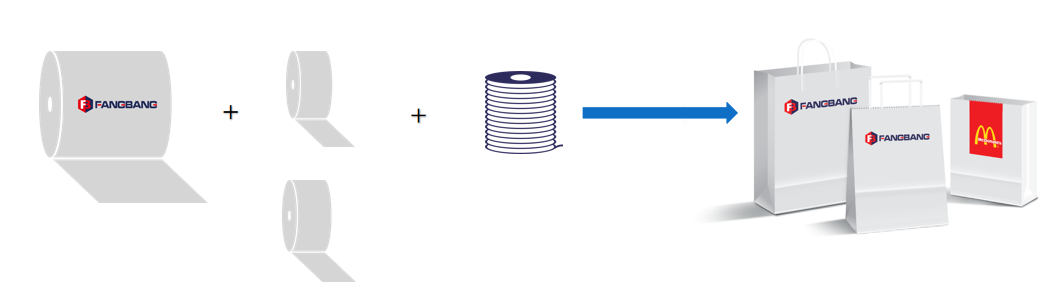

In today's eco-conscious world, paper bags have become a staple for businesses and consumers alike. But have you ever wondered how these ubiquitous carriers are made? Let's dive into the fascinating process of paper bag production using a state-of-the-art paper bag production line.

Step 1: Raw Material Selection

The journey begins with selecting high-quality kraft paper, which is both durable and eco-friendly. This paper is typically sourced from sustainable forests, ensuring minimal environmental impact.

Step 2: Printing and Design

Next, the paper is fed into a printing machine where custom designs, logos, or branding elements are added. Advanced printing technologies ensure vibrant colors and precise details, making each bag unique.

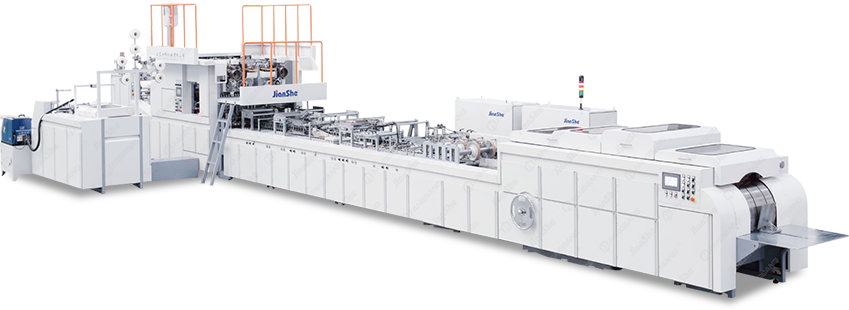

Step 3: Cutting and Creasing

The printed paper is then cut into precise shapes using automated cutting machines. Simultaneously, creasing lines are added to facilitate easy folding during the assembly process.

Step 4: Bottom Pasting

A crucial step in ensuring the bag's durability, the bottom pasting machine applies adhesive to the bottom flaps, which are then folded and pressed to create a sturdy base.

Step 5: Side Folding and Gluing

The sides of the bag are folded and glued together using high-speed folding machines. This step ensures the bag maintains its shape and can withstand heavy loads.

Step 6: Handle Attachment

For bags requiring handles, automated handle attachment machines are used. Handles can be made from twisted paper, flat paper, or even ribbon, depending on the design requirements.

Step 7: Quality Control

Each bag undergoes rigorous quality control checks to ensure it meets industry standards. This includes testing for strength, print quality, and overall durability.

Step 8: Packaging and Distribution

Finally, the finished bags are packed into bundles and prepared for distribution. Automated packaging systems ensure efficient and secure packaging, ready for shipment to businesses worldwide.

Environmental Impact

Modern paper bag production lines are designed with sustainability in mind. From using renewable resources to minimizing waste, these production lines contribute to a greener planet.

Conclusion

The paper bag production line is a marvel of modern engineering, combining efficiency, precision, and sustainability. By understanding the intricate process behind each paper bag, we can appreciate the innovation and effort that goes into creating these everyday essentials.

Next time you carry a paper bag, remember the sophisticated journey it has undergone—from raw material to a functional, eco-friendly product.