This Auto Sheet-Fed Paper Bag Machine is designed to transform single sheets of paper into high-quality square-bottom paper bags, complete with an upper folding mouth and reinforced bottom card—all in one seamless operation. It is the ideal equipment for producing middle and high-grade non-marking handbags, including:

Christmas paper goodie bags (perfect for festive gift packaging)

Elegant jewel paper bags (luxury retail and boutique use)

Durable brown paper bags (eco-friendly shopping & retail)

White paper bags with handles (wedding favors, premium branding)

Custom paper favor bags (events, parties, and promotions)

Key Features & Benefits:

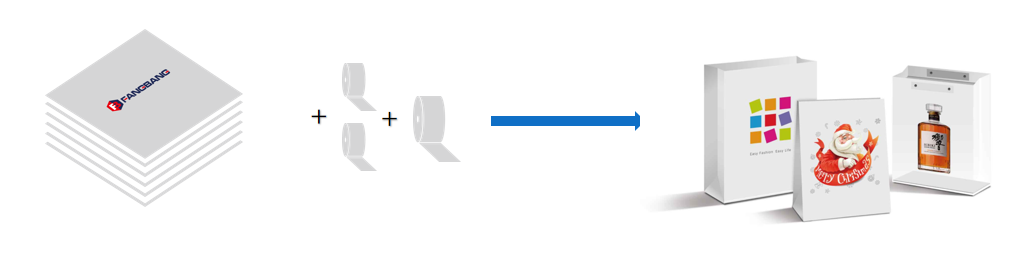

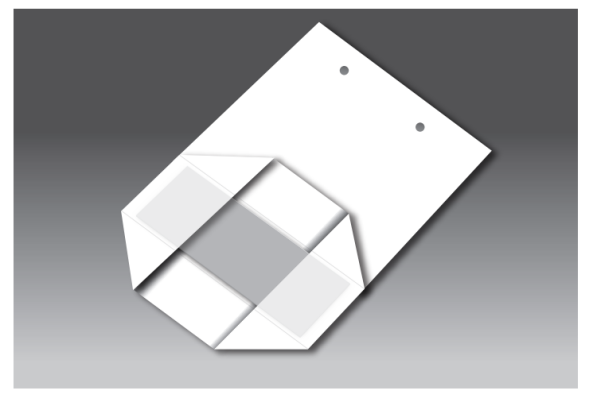

✅ All-in-One Automation – From raw paper feeding to bag folding, side gluing, bottom card insertion, and sealing, this machine ensures flawless bag formation while reducing labor costs.

✅ Non-Stop Feeding – Equipped with an advanced pre-stacking flyer for continuous operation, boosting production efficiency.

✅ Versatile Paper Compatibility – Handles a wide range of paper materials, making it perfect for producing:

Food-safe paper bags (grocery, bakery, takeout)

Fashion & garment bags (branded shopping bags)

Luxury gift bags (high-end retail, jewelry, cosmetics)

Christmas-themed paper bags (seasonal promotions, holiday packaging)

Ideal for Diverse Industries:

✔ Food & Beverage – Sturdy paper goodie bags for bakeries, cafes, and confectioneries.

✔ Fashion & Retail – Premium jewel paper bags and brown kraft bags for boutiques.

✔ Gifting & Events – Custom paper favor bags for weddings, parties, and Christmas promotions.

✔ Eco-Friendly Brands – Sustainable white & brown paper bags with handles for conscious consumers.

Upgrade your production with this high-speed, precision-engineered paper bag machine—perfect for businesses seeking efficiency, quality, and versatility in paper bag manufacturing.

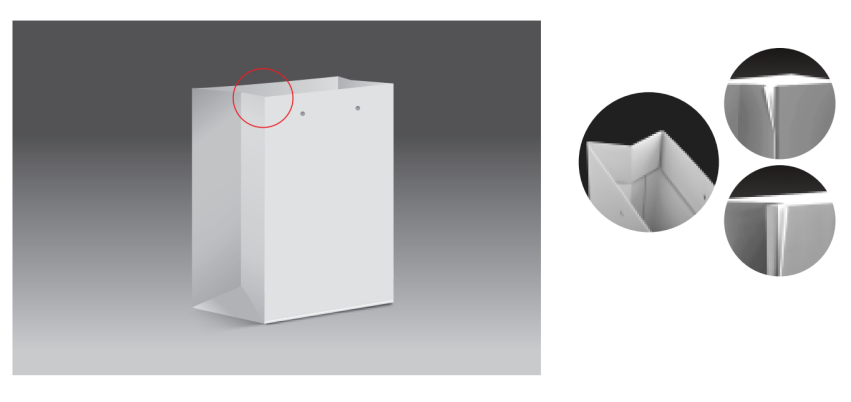

| 1 machine can produce 3 types of bag opening. |  |

| Automatic bottom card release function |  |

| TECHNICAL DATA | ZD-BFP08 | ZD-BFP18 | ZD-BFP20 |

| Paper Width | 390~780mm | 550~1250mm | 710~1320mm |

| Paper Length | 310-530mm | 310-630mm | 340-630mm |

| Paper Thickness | A:(Kraft Paper) 120~200g/m | A:(Kraft Paper) 120~200g/m | |

| B:(Art Paper )+(Laminated PP Film)155~250g/m | B:(Art Paper )+(Laminated PP Film) 155~250g/m | ||

| C:(White Cardboard)+(Laminated PP Film)180~250g/m | C:(White Cardboard)+(Laminated PP Film)180~250g/m | ||

| D:(Grey paperboard)+(Laminated PP Film) 150~300g/m | D:(Grey paperboard)+(Laminated PP Film) 150~300g/m | ||

| Bag Body Width | 120~250mm | 180~450mm | 240-500mm |

| Bag Body Height | 215~395mm | 240~480mm | 250~480mm |

| Bag Bottom Size | 60~130mm | 80~170mm | 100~170mm |

| Bag Mouth Fold Width | 25~50mm | 25~50mm | 25~50mm |

| Max. Speed | 40~60bags/min | 40~60bags/min | 40~60bags/min |

| Total Power | 12kw | 15kw | 15kw |

| Total Weight | 10000kg | 15000kg | 15000kg |

| Overall Dimension | L17300xW2200xH1700mm | L17300xW2500xH1700mm | L17300xW2600xH1700mm |

| Overall Dimension of Bottom Card Device | L2800xW1500xH1600mm | L2800xW1500xH1600mm |

This machine is ideal for processing medium and high-grade handbag by using single sheet of paper as raw material and co...

By additionally embed functional unit (flexo printing, dual-layer pasting, die-cut window making or patching & punching ...

This machine adds special features to the traditional roll paper bag machine, enabling it to make special e-commerce pap...

1. IntroductionToday, environmental consciousness is no longer just a trend—it’s a core consideration for both consumers...

A detailed guide to the industrial paper bag manufacturing process, from raw material preparation and printing to automa...

When it comes to purchasing valve bag making machines for building materials, what truly matters to buyers is one thing:...

GET A QUOTE